Seal Stacks

|

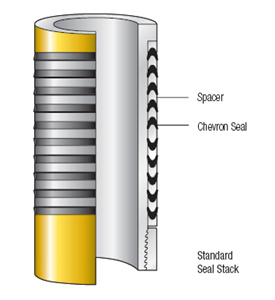

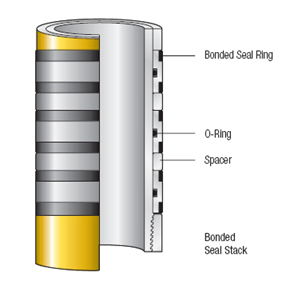

Standard Seal Stacks–made up of nitrile chevron seals and steel spacer rings. Should remain in seal-bore during service. Bonded Seal Stack–Two nitrile or Viton seals are bonded to each metal insert. These inserts are separated by steel spacers. Bonded seals should be used when seals cannot be prevented from moving out of the seal-bore while holding differential pressure. Also recommended for sealing low-pressure gas at low temperatures. |

|

|

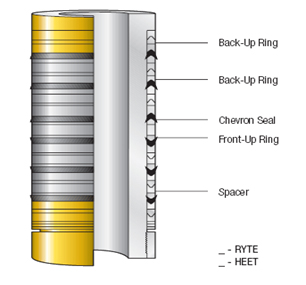

V-RYTE Seal Stack–Made up of Viton chevron seals with Teflon and Ryton* backup rings, Ryton front-up rings and steel separators. Should remain in seal-bore during service. A-RYTE Seal Stack–Made up of Aflas chevron seals with Teflon and Ryton backup rings, Ryton front-up rings and steel separators. Should remain in seal-bore during service. |

|

|

A-HEET Seal Stack–Made up of Aflas chevron seals with Teflon and HEET backup rings, HEET front-up rings and steel separators. Should remain in seal-bore during service. RYTE Seal Stack–Made up of PS006 chevron seals with Teflon and Ryton backup rings, Ryton front-up rings and steel separators. Should remain in seal-bore during service. |

|

|

Seal-RYTE Seal Stack–Made up of Perfluoroelastomer chevron seals with Teflon and Ryton backup rings, Ryton front-up rings and steel separators. Should remain in seal-bore during service. K-RYTE and K-HEET Seal Stacks–Made up of KALREZ brand Perfluoroelastomer chevron seals with Teflon and Ryton or HEET backup rings, Ryton or HEET front-up rings and steel separators. Should remain in seal-bore during service. |

|

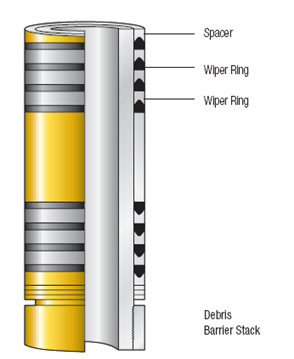

Debris Barrier Stack–Made up of Teflon and Ryton backup rings and Ryton front-up rings and steel

separators. Used as a wiper to prevent debris from damaging KRYTE, K-HEET, A-HEET or Seal-RYTE

seal stacks when seals are moved after being placed in service.